Powered by

AI Optimization Engine

The industry's only solution that successfully integrates AI technologies—including the Optimization Algorithm Engine and Machine Learning—to accurately predict each product’s future cycle time at every workstation and generate optimal production planning. This enables automated production planning, surpasses manual operations, and significantly enhances manufacturing efficiency.

Dynamic Adjustment of Production Status & Demand

The system automatically predicts cycle time based on order status and factory characteristics, sets production targets for each workstation, and provides daily, weekly, and monthly production plans while optimizing bottleneck scheduling. This improves production stability and efficiency, achieving maximum capacity utilization.

Seamless Integration with Existing Manufacturing Data

With highly flexible customization capabilities, the system supports factories with or without MES. It adapts to industry- or site-specific requirements, quickly integrates existing production management data, and enables seamless deployment of intelligent production scheduling.

When Is the Right Time to Implement APS?

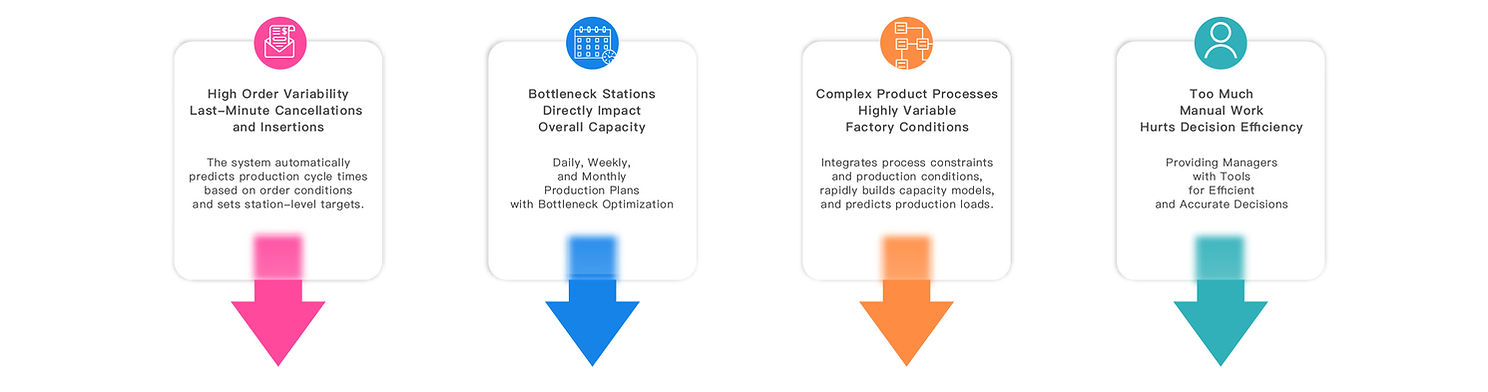

As product mixes grow more complex and rush orders increase, factories face bottlenecks, WIP buildup, delivery instability, and inconsistent planning. This is the moment to adopt APS — a smart scheduling system that ensures capacity balance, stable delivery, and efficient production.

Build a Tailor-Made AI Smart Production Solution for Your Enterprise

Based on order requirements, machine configuration, capacity constraints, and historical production data, the system uses an intelligent AI optimization engine combined with machine learning to automatically build capacity models tailored to each factory. It quickly predicts future cycle times and load at each workstation, generates optimal material feed-in plans, and produces multi-objective production plans (daily, weekly, monthly).

It further optimizes bottleneck scheduling, ensures maximum bottleneck utilization, improves on-time delivery, and maximizes capacity and profit—providing managers with fast and accurate decision-making tools.

Which Industries

Can Use APS?

APS can be effectively implemented in semiconductor, PCB, panel, electronic components, biomedical, CNC machining, and various manufacturing sectors.

YouThought APS has been successfully deployed in numerous semiconductor, PCB, panel, biomedical, and CNC factories, significantly improving productivity and on-time delivery. It accelerates AI-driven smart transformation and leads manufacturers toward the next generation of intelligent factories.

Semiconductor

PCB

Panel

CNC Machining

Electronic Components

Biomedical

Textile & Footwear

Food & Pharma

Subscribe for the Latest Updates

Stay informed with the latest insights on AI Smart Manufacturing.